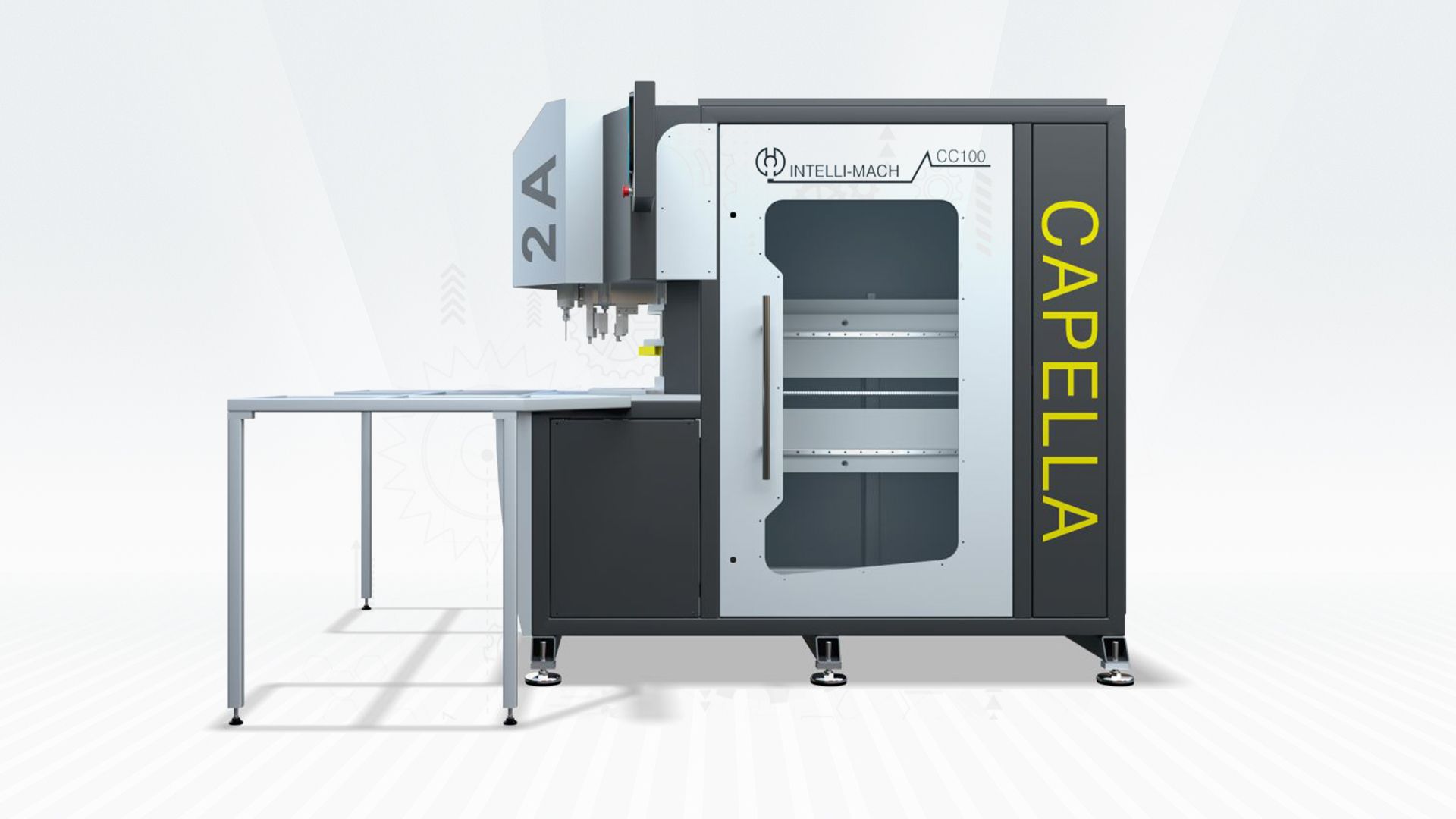

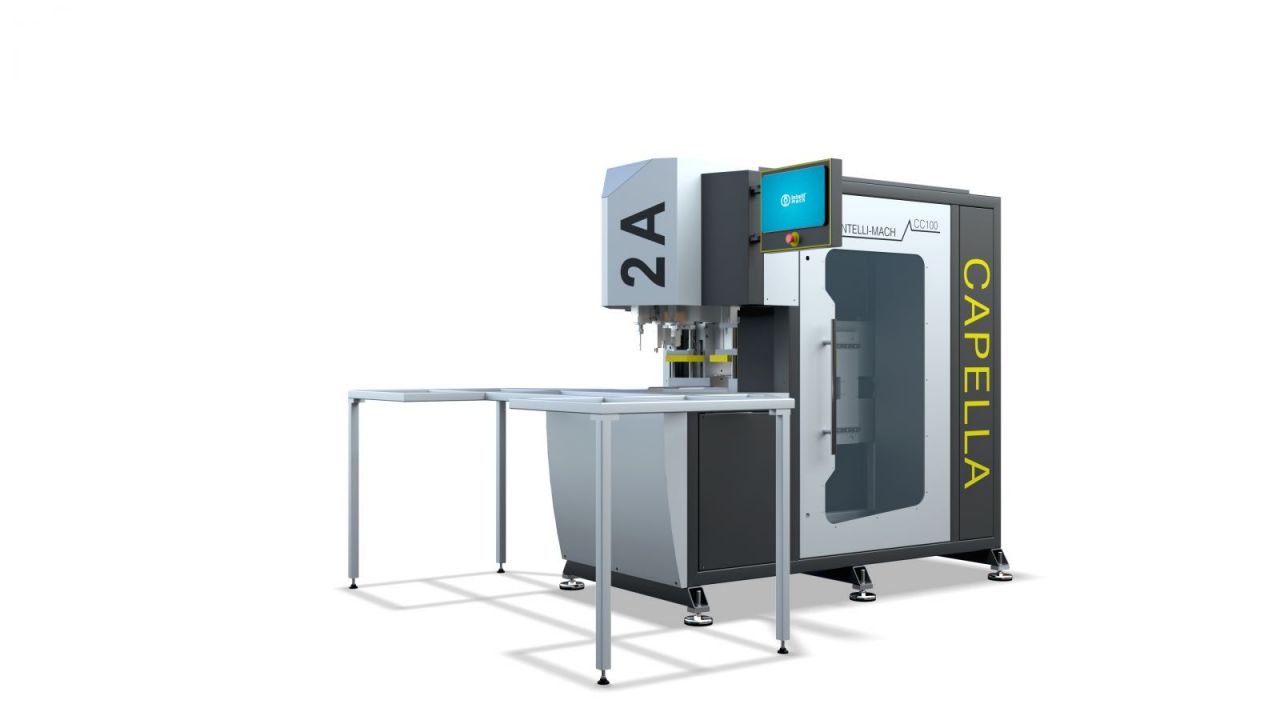

CNC PVC Profile Corner Cleaning Machine CAPELLA CC100

" CAPELLA CC100 CNC PVC Profile Corner Cleaning Machine

Technical Features

CNC PVC Profile Corner Cleaning Machine

Designed to clean the corners of PVC profiles from welding seals.

Standard specifications

– High speed precision control system with 2-axis servo motors.

– Ability to define and recognize different profile heights.

– Surface cleaning tool selection feature according to colored or white

profiles.

– Allow remote connection and control access via network connection.

– Industrial PC based control panel unit

– Easy file transfer with USB

– 15 inch touch screen.

– Automatic Lubrication System

– It has the ability to define and process files in dxf and dwg formats created in

cad programs with Windows-based PC operating system.

– Maximum 200 mm minimum 40 mm profile processing range.

– Ability to operate with 11 tools.

Optional Features

– Optionally, it can be connected to a 2-axis robotic turning station and can be adapted to a 4-corner welding machine.

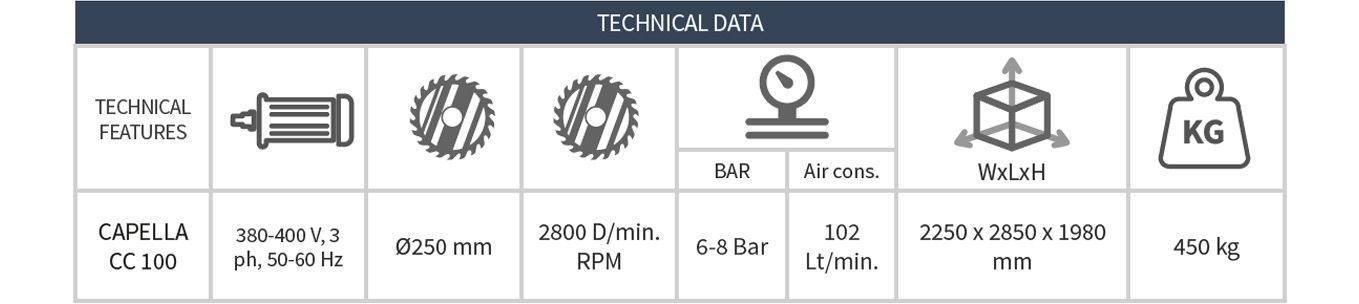

TECHNICIAL SPECIFICATIONS

| Power Supply | 380-400 V, 3 ph, 50-60 Hz |

| Power Consumption | 7 kw , 17 A |

| Saw Blade Speed | 2800 rpm |

| Drillers Speed | 14000 rpm |

| Air Consumption | 102 lt/dk |

| Air Pressure | 6-8 bar |

| Daily Product | 200-240 frames ( 8 hours ) |

| Machine Weight | 1054 Kg |

| Maximum Workable Profile Height | 200 mm |

| Minimum Workable Profile Height | 40 mm |

| Maximum Workable Profile Width | 130 mm |

| Saw Outside Diameter | Ø250 mm |

| Saw inside Diameter | Ø30 mm |

| Saw Thickness | 4-4,3 mm |

SPECYFIKACJA TECHNICZNA

LANGUAGE

LANGUAGE